While external mixture formation processes (e.g., PFI) always produce a homogeneous mixture, both homogeneous and inhomogeneous mixtures can be realized by hydrogen direct injection (DI). In the trade-off between low nitrogen oxide emissions and high efficiency, DI offers optimization potential through many degrees of freedom, such as timing of injection, nozzle geometry, or multiple injections. As for gasoline DI, inhomogeneous operation is attractive especially for part load conditions. The ideal inhomogeneous mixture preparation – good ignitable, fast burning mixture around the spark plug, clean air near the walls -is in some respects more achievable for hydrogen than with hydrocarbons due to the extremely wide ignition limits. However, with significant mixture inhomogeneity, cyclic variations not only become technically more relevant, but also more complex in their underlying causal chain than with homogeneous mixture.

The primary objective of this subproject is to obtain a detailed understanding of the direct injection – mixing – ignition subchain in hydrogen-fueled engines. This is done by experiments in close cooperation with simulations in other subprojects. Therefore, another important goal is to provide data from the experiment for the validation of the simulation methods and vice versa the joint analysis of the simulations for a more complexe explanation and evaluation of the experimental results. Exemplary questions here are:

- How do the cyclic variations behave as a function not only of the global but also of the local fuel-air ratio?

- How can the influence of flow and mixing on combustion be traced back in time?

- Is there a tracer for single-shot LIF of gaseous hydrogen that is suitable for high injection pressures and fired operation?

- […]

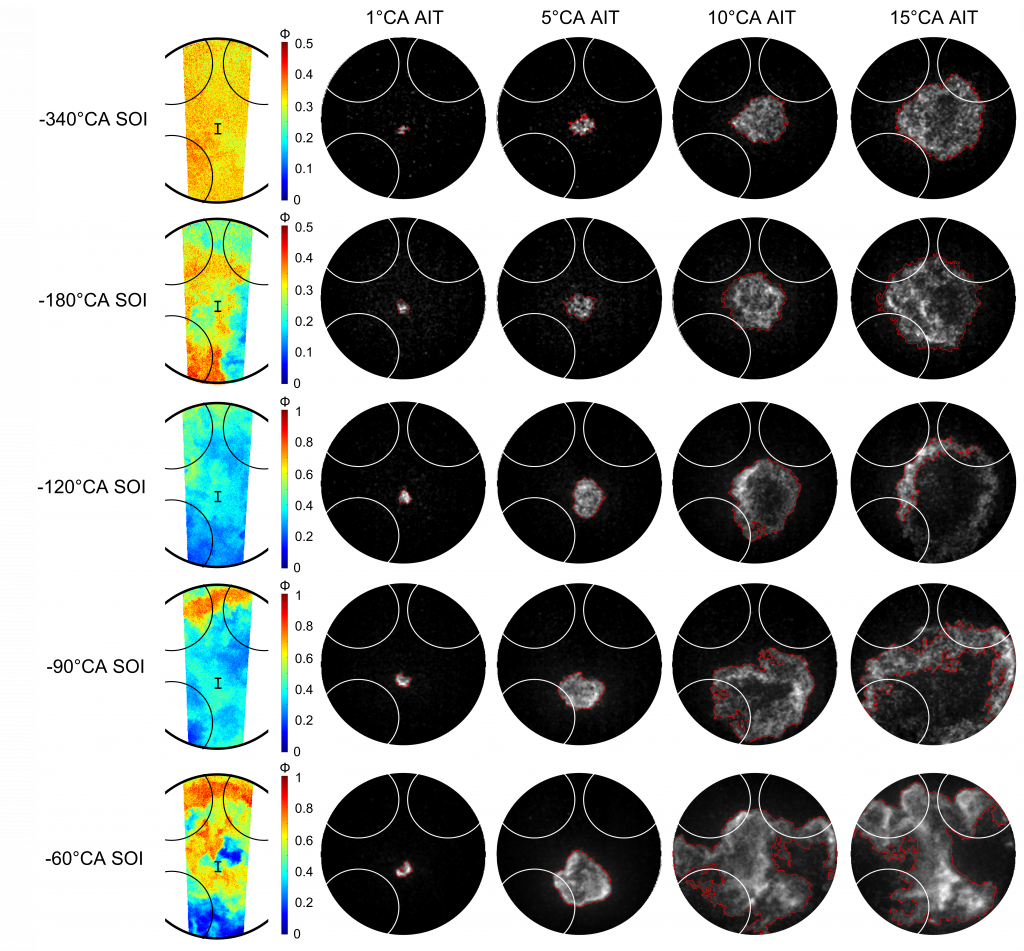

Figure 1. Single shots of the equivalence ratio at ignition timing at different SOIs and corresponding flame propagation [1].

References

[1] Laichter, J., Kaiser, S., Rajasegar, R., and Srna, A.: Optical Investigation of Mixture Formation in a Hydrogen-Fueled Heavy-Duty Engine with Direct-Injection, SAE Technical Paper 2023-01-0240, 2023, https://doi.org/10.4271/2023-01-0240.

Contact:

Prof. Dr. Sebastian Kaiser sebastian.kaiser(at)uni-due.de

Judith Laichter judith.laichter(at)uni-due.de